Expertise

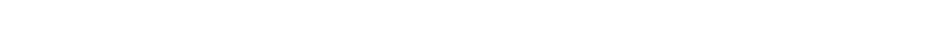

Complete Sugar Refinery Plant

In recent years the on-going trade liberation and the shifting in production base has seen the emerging of new sugar refineries. As a result, SU-ENCO has been supplying refinery plants on a turn-key basis to Philippines, Indonesia, Bangladesh, and local Thailand markets among other places as well as equipment supply to several other countries in Asia and the Middle East. The SU-ENCO sugar refinery design and supply range from 400 ton/day to 3,000 ton/day. The plants are equipped with latest technology which minimize energy (electricity and steam) consumption and maximize the sugar output yield. The plants' automation levels can be tailor made according to different man power requirement in different countries.

With the latest technology in engineering software, it allows the plants to be completely designed in 3-dimensions. This contributes greatly in reducing the project completion schedule as well as the precision in terms of issuing the bill of materials for piping, valves and fittings, and other steel structures. Combining practical design with experienced specialists, SU-ENCO can assist the project owner during the construction for the site survey, inspection and eventually operation assistant during start up and commissioning.

Equipment List

- Weighing Scale

- Lime Slaker

- Carbonators

- Rotary Pressure Filters

- Fillter Press

- IER Decolorization

- Evaporation

- Refined Massecuite Pans

- Surface Condenser

- CO2 Purification Plant

- Refinerd Sugar Dryer-Cooler

- Water Treatment